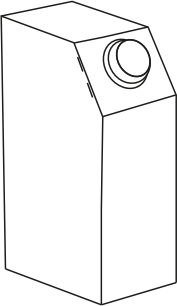

FOLDING BOXES

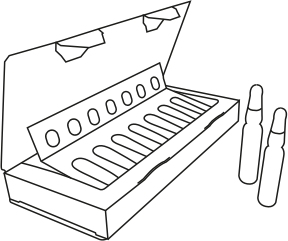

Even for the classic packaging item, there are no standard solutions here. Each folding box is tailor-made for its contents, must fit perfectly and protect securely against damage and spoiling. The box not only communicates all the important information about the product, it also arouses emotions which influence the purchasing decision.

High-quality materials and effects induce desire and turn unboxing into an experience. Intelligent additional functions produce smart solutions. This is how we create our packaging experience.